With the Bulletproof Design of the Hollis HP5 Non-Balanced Flow-By Piston First Stage the HO2 First Stage is Certified for up to 100% Oxygen Service thanks to Highly Specialized Component Materials and Manufacturing Processes. Cleaned and Assembled in a Clean Room Environment with Specially Designed Materials, Halocarbon Based Lubricants and Color- Coded for Easy Identification

Details

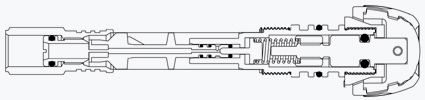

The Flow-By Piston Design is the only true Fail-Safe First Stage Design on the market. The Piston will automatically move Downstream from the High Pressure Air coming from the Scuba Cylinder if there is an unexpected malfunction of the High-Pressure Seat. This feature guarantees a constant Gas-Flow to the Second-Stage Regulator. The Regulator First Stage weighs 8.3 oz (235.3 g).

PNEUMATICALLY BALANCED VALVE

The pneumatically balanced second stage reduces breathing resistance to near zero with a balanced valve seat designed to respond to the slightest inhalation.

A pneumatically balanced second stage actually has (or can have) the same initial crack opening effort as a mechanically balanced, but the spring force of a pneumatically balanced second stage is lighter so it’s spring rate is also lower.

Therefore the force required to open the valve farther as flow increases is less than that required for a mechanically balanced second stage with a higher rate spring. So the total effort to breathe the pneumatically balanced second stage is indeed less.

The spring force must be just enough to overcome the difference between downstream air pressure and upstream balance chamber pressure.

The downstream air travels through a hole in the poppet into the balance chamber and applies an “upstream” force just slightly less than the downstream force.

DIVER ADJUSTABLE INHALATION EFFORT

A simple twist of the adjustment knob enables complete control…

Set the inhalation requirement to near zero when you need ultimate performance, or tune it for greater resistance as conditions or preferences change.

Most downstream demand valve regulators are calibrated during manufacturing to a single, ‘middle of the road’ operation. Whether finning up current at 100+ feet or merely snorkeling out to the dive site, this factory adjustment may not be optimum for the wide variety of demands we place on our equipment.

Features

- Bulletproof Hollis HP5 First Stage Design

- Non-Balanced Flow-By Piston

- Fail-Safe First Stage Design

- 300 BAR/4500 PSI DIN Connection

- DIN Hand-Wheel Connector: Oxygen Green for Easy Identification for Oxygen-Use-Only

- Material: Durable and Corrosion Resistant Marine-Grade Chrome Plated Brass

- 4 LP 3/8" Threaded Ports

- 1 HP 7/16" Threaded Port

Hollis 150LX 2nd Stage

- Pneumatically balanced chrome-plated brass valve results in smooth, easy breathing

- Reversible demand valve, can be converted from right-handed hose configuration to left handed hose configuration

- Adjustable Dive/Pre-Dive switch: Large Venturi lever has a soft rubber grip, which makes it easy to locate and use

- Ergonomic exhaust channels bubbles away from field of view and reduces exhaust effort

- Improved orthodontic mouthpiece with dual color tabs

- Stainless steel cosmetic ring

- Suitable for coldwater diving

- Lifetime Warranty

- Free Parts for Life

- 2-Year Service Interval with Inspection